Volume 2 - Year 2016 - Pages 24-28

DOI: TBA

Mineralogical Characterisation of Tantalum Ores for the Optimization of their Processing

Pura Alfonso1, Josep Oliva1, Maite Garcia-Valles2, Oriol Tomasa1, Daniel Calvo1, Eduard Guasch1, Hernán Anticoi1, David Parcerisa1

1Universitat Politècnica

de Catalunya, Dept. d'Enginyeria Minera i Recursos Naturals

Av. de les Bases de Manresa 61-73, 08242, Manresa, Spain

pura@emrn.upc.edu; josep.oliva@upc.edu

2Universitat de Barcelona, Dept. de Cristal·lografia, Mineralogia i Dipòsits Minerals

Carrer Martí i Franquès, s/n, 08028, Barcelona, Spain

maitegarciavalles@ub.edu

Abstract - Tantalum is a strategic metal with multiple applications for the new technologies. Tantalum ore deposits are scarce in the European Union, thus, more efficient extracting processes are necessary to contribute to a greater European independence on the market of these critical raw materials. Tantalum mainly occurs in pegmatites, leucogranite deposits and its placers. There are not active tantalum mines in Europe, however, several deposits are susceptible to being exploited if current technologies of processing are improved. This work is part of the Optimore Project which aims to develop model and control technologies, using advanced sensing and advanced industrial control by artificial intelligence techniques, for more efficient and flexible tantalum and tungsten processing from crushing to separation process. In this paper, a characterization of tantalum ores from leucogranite and alluvial deposits is presented. This study will be used as a basis for designing the milling experiments to optimize the tantalum recovering during the processing. In the ore deposits, tantalum appears as a solid solution with niobium forming complex oxides which constitute small size aggregates. Tantalum ores, which are characterised here, belong to alluvial placers of pegmatitic origin located in the Bolivian Amazon Craton and to leocogranites of Penuota, Spain. Most of tantalum-bearing minerals of the Bolivian placers belong to the columbite group minerals, whereas in Penouta, microlite is more abundant. Columbite usually exhibit a concentric zoning, whin a Nb-rich core and a Ta-rich rim.

Keywords: Tantalum, Ore processing, Milling, Mineralogical characterization, tantalite, Microlite

© Copyright 2016 Authors This is an Open Access article published under the Creative Commons Attribution License terms. Unrestricted use, distribution, and reproduction in any medium are permitted, provided the original work is properly cited.

Date Received: 2015-10-30

Date Accepted: 2015-03-24

Date Published: 2016-10-19

1. Introduction

The present work is part of the Optimore project [1] which aims to optimize the crushing, milling and separation ore processing technologies for Tungsten and Tantalum during the mineral processing. This project searches the use of improved fast and flexible fine tuning production processes control based on new software models and advanced sensing. It is expected to increase the recovering in 7-12% on the current best production processes and increase energy saving on a 5% compared to the best available techniques. The development of specific tools for the processing of tantalum will contribute to optimize the production with lower costs for their production.

2. Related Work

Tantalum is a strategic metal with a wide number of applications. New technologies, leading to the miniaturisation of electronic devices have resulted in increased use of tantalum. Tantalum-based capacitors, in particular, are on the rise, then, they are increasingly used in automotive electronics, mobile phones, personal computers and wireless devices [2].

Over 80% of the world's tantalum supply comes from Africa particularly from the Democratic Republic of Congo and Rwanda. Most of the current production from Congo drives to strong social and environmental conflicts [3, 4, 5]. In addition, in this country child labour is being used for this mining activity [6]. Nb and Ta are considered as critical metals by the European Union [7] and then, new deposits of supply should be developed to diversify geographic sources of supply [2]and somehow contribute to the reduction of this social scourge

The use of models and parameter adjustment processes increases the optimization of ore raw materials processing, while the use of artificial intelligence techniques allows a better process control. Recently many systems of automatic chemical and morphological analysis of particles have emerged [8, 9]. This automated mineralogical characterization is obtained using an advanced Scanning electron microscopy system (SEM) that combines the functions of the energy dispersive X-ray spectrometry (EDX) for the chemical analysis and the digital image analysis of back-scattered electron (BSE) micrographs. This technique can be applied for mineral characterization on line, from the raw material examination to the processing. In the present project these analyses will facilitate the design of sensing systems for controlling during the mineral processing of the tantalum ore.

3. Materials and Methods

Tantalum in Europe mainly occurs in leucogranites located in the west part of the continent. The ores used in the present project come from the rare-element enriched leucogranites from the Sn, Ta Penouta mine, located in Galicia, Spain. This mine was primarily exploited for Sn and now it is planned to reopen not only for obtaining Sn but also for tantalum.

In addition, in this study a high grade Ta-rich deposit is used. This is a Placer deposit, which was formed from the weathering of rare-element pegmatites, located in the Bolivian Amazonian Craton, near the border with Brazil.

The mineralogy and mineral chemistry of the studied ores was determined. Previously the chemical analyses of whole rock were performed in the Activation Laboratories (ACTLABS) of Canada.

The mineralogy was obtained by scanning electron microscopy with energy-dispersive spectral analysis (SEM–EDS) used in the back-scattered electron mode (BSE). The mineral chemistry was performed using a JEOL JXA-8230 electron microprobe in the Centres Cientifics i Tecnològics de la Universitat de Barcelona.

4. Mineralogy and chemistry of tantalum bearing minerals

Tantalum occurs in a great variety of oxide minerals. The most common are columbite, tantalite and microlite. Columbite and tantalite are the end members of a solid-solution called the columbite-group minerals, (Fe,Mn)(Nb,Ta)2O6. Microlite, (A)2(B)2O6(O,OH,F)), with A=REE,U,Y, Ca,Na nd B=Ta,Nb, Ti, is the Ta-rich member of the pyrochlore group minerals. Tantalum can also occur in the structure of cassiterite, SnO2, in substitution of Sn.

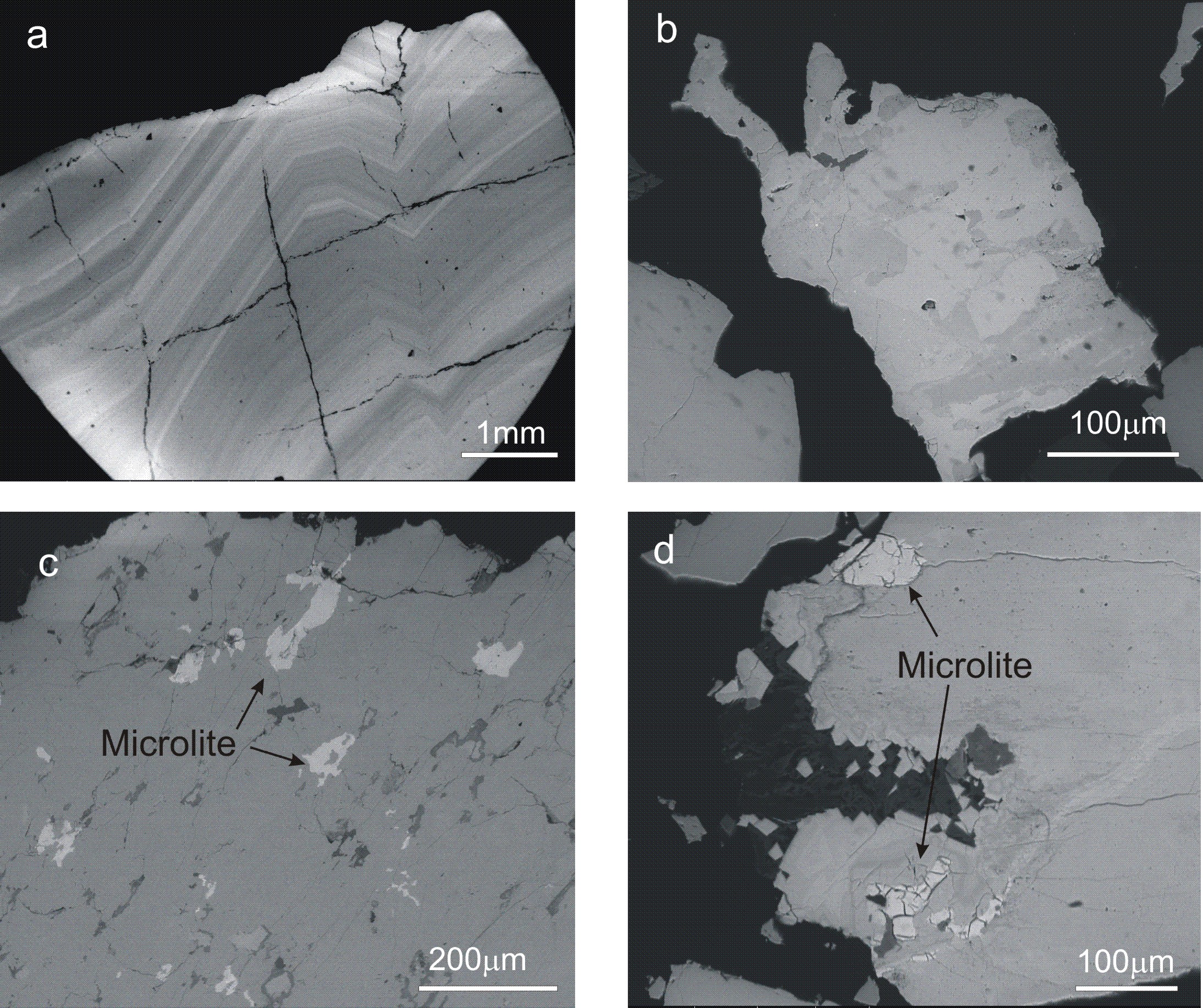

In columbite and pyrochlore group minerals the distribution of Nb and Ta in the mineral may be uniform, but most commonly these elements are irregularly distributed, giving place to minerals with zoned textures (Figure 1). The optimal design of the milling operations during the processing lies in the structural characterization of these minerals in order to obtain a relatively high degree of Ta2O5 richness of the concentrate.

In the ore from Bolivian alluvial deposits, most grains of the Nb-Ta bearing minerals belong to the columbite group. Their composition is mainly ferrocolumbite, and in minor amounts, manganocolumbite. Columbite occurs as subhedral tabular dark brown crystals, up to 1 cm in size. Some grains are homogeneous but most are zoned. Zoning can be oscillatory, with multiple light, Ta-rich, and dark, Nb-rich, bands and irregular patchy zoning (Figure 1). These zoning types are common for tantalum minerals in pegmatitic occurrences [10, 11].

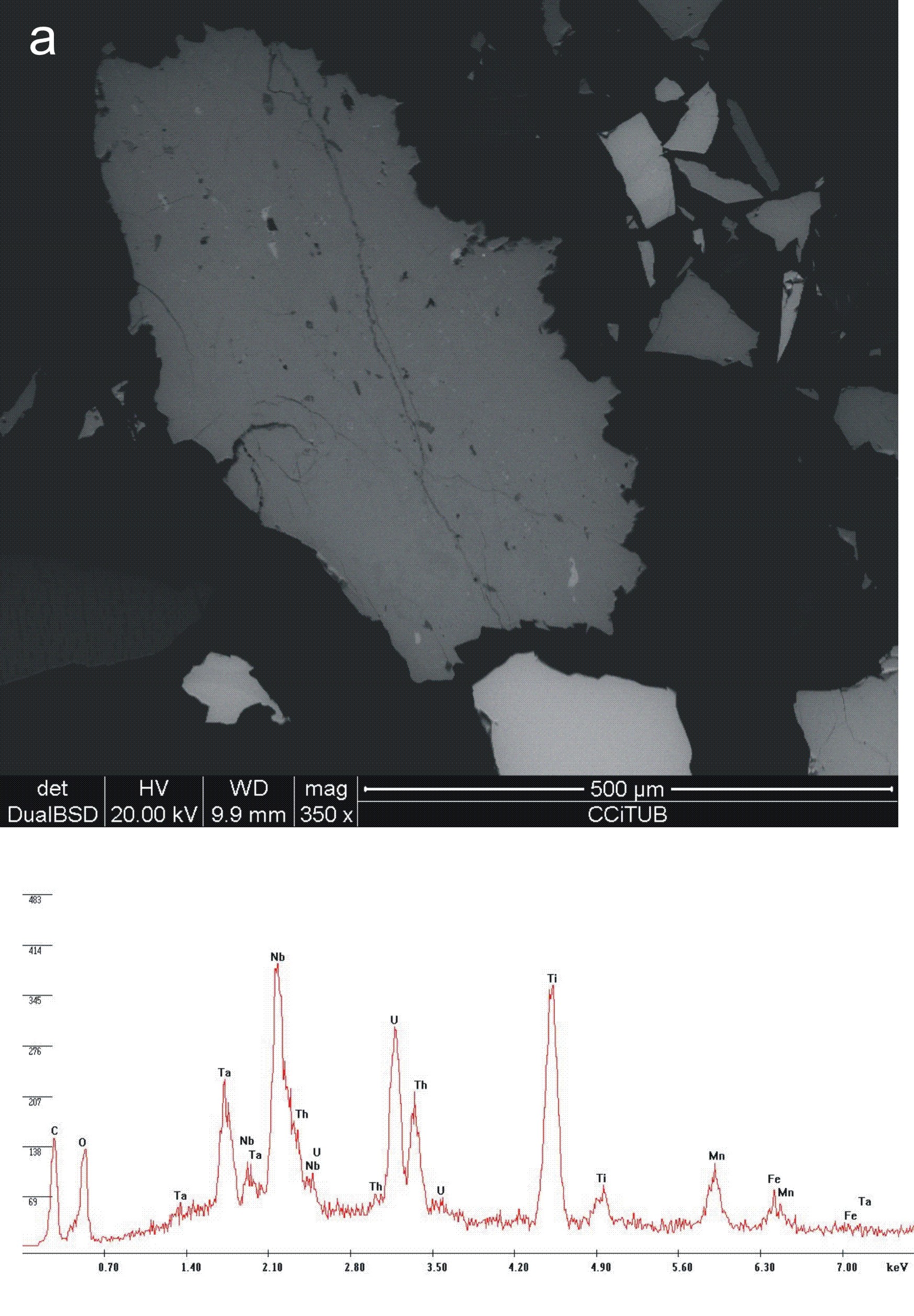

In the Bolivian deposit microlite is the most common mineral of the pyrochlore group. In all cases the content of Pb, Sb and Bi was negligible. Ta/(Nb+Ta) ratios in microlite vary from 0.75 to 0.91. The most abundant cation in A site is Ca, with 0.87 to 1.24 atoms per formula unit (apfu); Na attains from 0.43 to 0.79 apfu. The U content decreases with the Ta/(Nb+Ta) ratio; it can reach up to 0.31 apfu and Th can be up to 0.01 apfu. Sn can reach up to 0.06 apfu.and W, up to 0.01 apfu. Fluorine has not been analysed because it was not detected with SEM-EDS.

In addition to the relatively high radioactive elements present in microlite, other Uranium and Thorium-rich late phases are common in these ores (Figure 2). The chemical analysis of the concentrate reported 0.14 wt.% of U3O8 and 0.39 wt.% of ThO2. These high contents in radioactive elements should be avoided in order to commercialize the Ta ores

Columbite has been altered along fractures with the crystallization of new minerals. Often, in these areas the reaction of late fluids with columbite produces the substitution of columbite by fersmite, (Ca,Ce,Na)(Nb,Ta,Ti)2(O,OH,F)6, and the formation of Ta-rich phases as Ishikawaite, ((U,Fe,Y,Ca)(Nb,Ta)O4 and microlite. Nb-Ta rich ilmenorutile and strüverite ((Ti,Ta,Fe)O2), up to 16 wt% of Ta2O5, also occur as small grains replacing columbite. All these phases are of few microns in size. As a result, it is difficult to separate themfrom the rest of the particle.

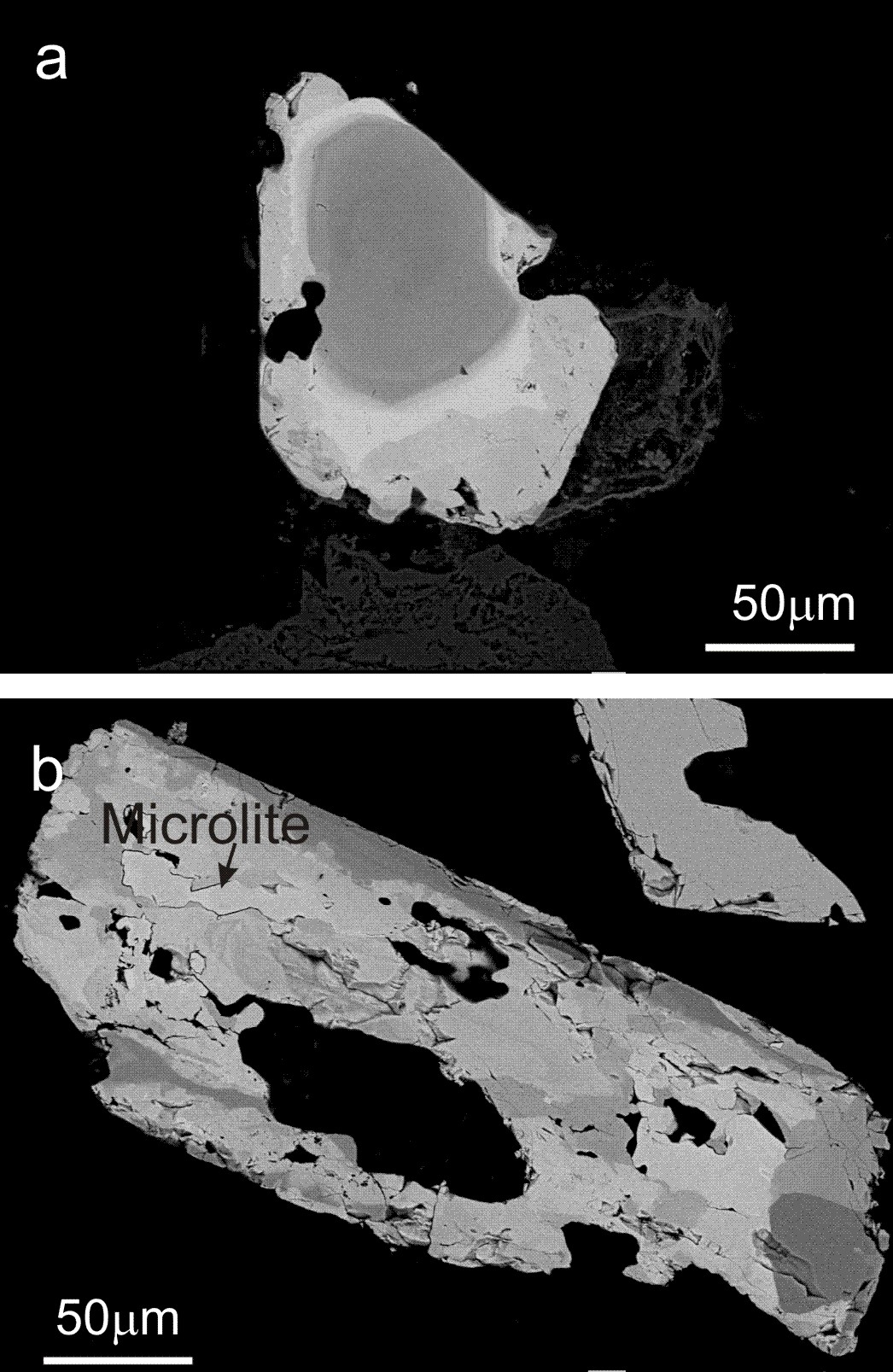

In leucogranites from Penouta the Nb-Ta bearing minerals are scarce; preliminary chemical analyses show concentrations of no higher than 150 ppm of Ta. Chemical composition and textures of Ta bearing minerals of these leucogranites contrast with the obtained ones from the Bolivian deposit. In Penouta, the columbite group minerals are mainly mangano-columbite and mangano-tantalite. Crystals can be homogeneous and zoned; The ones with a relatively homogeneous Nb-rich core and a Ta-rich rim are abundant (Figure 3).

Microlite is also abundant in these ores, but it occurs in small grains, usually lower than 20 microns in size. Wodginite, Mn(Sn,Ta)(Ta,Nb)2O8, and Ta-rich cassiterite also occur (Table 1).

Table 1. Representative chemical compositions of cassiterite from Penouta.

| a-11 | a-17 | b-94 | b-211 | |

| WO3 | 0.03 | 0.11 | 0.07 | 0.00 |

| Nb2O5 | 0.25 | 0.87 | 1.68 | 0.00 |

| Ta2O5 | 1.34 | 6.27 | 9.77 | 0.12 |

| SnO2 | 98.19 | 91.53 | 87.40 | 99.38 |

| TiO2 | 0.08 | 0.00 | 0.01 | 0.00 |

| PbO | - | - | 0.00 | 0.08 |

| FeO | 0.29 | 1.02 | 1.68 | 0.03 |

| MnO | 0.03 | 0.26 | 0.65 | 0.00 |

| Total | 100.21 | 100.21 | 101.37 | 99.61 |

| Atoms per formula unit | ||||

| W6+ | 0.000 | 0.001 | 0.000 | 0.000 |

| Nb5+ | 0.003 | 0.010 | 0.019 | 0.000 |

| Ta5+ | 0.009 | 0.042 | 0.065 | 0.001 |

| Sn4+ | 0.977 | 0.908 | 0.849 | 0.992 |

| Ti4+ | 0.002 | 0.002 | 0.000 | 0.000 |

| Pb2+ | - | - | 0.000 | 0.000 |

| Fe2+ | 0.025 | 0.085 | 0.137 | 0.002 |

| Mn2+ | 0.001 | 0.006 | 0.013 | 0.000 |

| ∑Cat. | 1.015 | 1.053 | 1.088 | 1.002 |

5. Conclusion

The mineralogical characterization of tantalum ore is necessary to determine the grade that could be obtained during the ore processing.

Nb and Ta occur as a solid solutions in different oxide minerals. In some cases as in the Penouta leucogranite, the Nb-rich and the Ta-rich zones of the mineral particle could be separated with a conventional degree of milling, obtaining a high degree of T2O5 content in the concentrate. In other cases, these metals are completely mixed or distributed in very narrow zones, preventing it separation by physical methods.

The high contents in radioactive elements in the ore from the alluvial Bolivian deposits suggests the application of a treatment to reduce them before being place on the market.

Acknowledgements

This work is part of the OptimOre project. This project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 642201. The Strategic Minerals enterprise helped in the sampling of Penouta and Telos World provided the Bolivian samples. Ana Domingo and Eva Prats assisted with the SEM observations and Xavier Llovet with the microprobe analyses.

References

[1] OptimOre, " Increasing yield on Tungsten and Tantalum ore production by means of advanced and flexible control on crushing, milling and separation process.," [Online]. Available: https://optim-ore.eu/optimore_project. [Accessed 1 April 2015].View Article

[2] G. J. Simandl and D. A. R. Mackay, "Geology, market and supply chain of niobium and tantalum—a review," Miner. Deposita, vol. 49, no. 8, pp. 1025-1047, 2014. View Article

[3] R. Milburn, "The roots to peace in the Democratic Republic of Congo: conservation as a platform for green development," International Affairs, vol. 90, no. 4, pp. 871-887, 2014. View Article

[4] R. Bleischwitz, M. Dittrich and C. Pierdicca, "Coltan from Central Africa, international trade and implications for any certification," Resources Policy, vol. 37, pp. 19-29, 2012. View Article

[5] N. Greve, "Tungsten, tantalum, rare earths emerging "critical" global metals," Mining Weekly, 3 July 2013. View Article

[6] E. K. Smith, J. A. Cazier, J. Fox and J. M. Kitunda, "The effect of child labour in Africa on consumers of the cell phone industry," Int. J. Information Systems and Change Management, vol. 6, pp. 147-159, 2012. View Article

[7] European Commission, "Report on Critical Raw Materials for the EU: Report of the Ad hoc Working Group on defining critical raw materials," European Commission, Brussels, Belgium, 2014. View Article

[8] D. Pirrie, M. R. Power, G. K. Rollinson, P. E. J. Wiltshire, J. Newberry and H. E. Campbell, "Automated SEM-EDS (QEMSCAN®) Mineral Analysis in Forensic Soil Investigations: Testing Instrumental Reproducibility," in Criminal and Environmental soil Forensics, Springer, 2009, pp. 411-430. View Article

[9] P. Sylvester, "Use of the Mineral Liberation Analyzer (MLA) for mineralogical Studies of sediments and sedimentary rocks," in, "Quantitative Mineralogy and Microanalysis of Sediments and Sedimentary Rocks," Mineralogical Association of Canada Short Course Series, vol. 42, pp. 1-16, 2012. View Article

[10] P. Alfonso, M. Corbella and J. C. Melgarejo, "Nb-Ta- minerals from the Cap de Creus pegmatite field, eastern Pyrenees: distribution and geochemical trends," Mineral Petrol, vol. 55, pp. 53-69, 1995. View Article

[11] A. G. Tindle and F. W. Breaks, "Columbite-tantalite mineral chemistry from rare element granitic pegmatites: Separation Lake area, NW Ontario, Canada," Mineral Petrol, vol. 70, pp. 165-198, 2000. View Article